Ortur Laser Master 3: The best cheap laser engraver / cutter.

Ortur is renowned for making some of the best laser engravers/cutters on the market. It has an affordable price. We also tried the Laser Master 2 and the Ortur Laser Master 2 Pro, they were both excellent.

When the Ortur Laser Master 3 engraver / cutter was released, we had to test it to see how this new version behaved.

Our team tried and tested the Ortur Laser Master 3 to see how this inexpensive laser engraver/cutter performs. You will also discover some of the most popular accessories, so you can decide if you want to complete your device.

You might also be interested in: The best cheap gaming laptop

Features

| Work zone: | 400x400mm |

| Dimensions: | 580x550x180 mm |

| Weight: | 6.5kg |

| Engraving speed: | 0 to 20mm/min |

| Laser wavelength: | 455 nm |

| Spot size: | 0.05 × 0.1mm |

| Precision: | 0.01 mm |

| Laser power: | 10w |

| Maximum cutting depth: | Acrylic 30mm | 20mm wooden board |

| Compatible materials: | Wood, acrylic, metal, ceramic, paper, cardboard etc… |

| Engines: | Two 42×60 Y XL stepper motors |

| connectivity: | Wifi, USB, SD card, IOS and Android App, U-disk |

| Light output: | LU2-10A (9500 – 10500mw) |

| Compatible software: | LightBurn, LaserGRBL, Laser explorer |

| Compatible files: | JPG, PNG, BMP, SVG etc. |

| Warranty: | 1 year |

Business ideas with a laser engraver / cutter

Laser cutters are very versatile production devices that can be used for many applications. Companies in all sectors can use these machines to improve their production process and increase their productivity. If you are looking to start a new business for example or to improve an existing business, here are some business ideas with a laser cutter:

Manufacture of mechanical parts: Laser cutters can be used to cut materials such as stainless steel, aluminum, copper and brass. Mechanical companies can use these machines to create spare parts, prototypes, and machine parts.

Advertising industry: Laser cutters can be used to cut materials such as wood, glass, plastic, and rubber. Advertising companies can use these machines to create promotional items and logos.

Jewelry making: Laser cutters can be used to cut materials such as gold, silver, copper, and brass. Jewelry businesses can use these machines to create unique and personalized jewelry.

Toy making: Laser cutters can be used to cut materials such as wood, plastic, and rubber. Toy companies can use these machines to create unique and fun toys.

Custom cutting services: laser cutters can cut different materials, you could offer custom cutting services for individuals or companies who are looking for unique pieces for their projects.

Sell original products on Etsy with the Ortur LM3

Etsy is a popular e-commerce site that allows independent designers to sell their handcrafted products. Laser engravers and cutters are increasingly popular production tools that allow designers to produce unique and personalized products to a high level of precision and quality. Here's how to use a laser engraver/cutter to improve your business on Etsy:

Customization of products: Laser engravers and cutters make it possible to personalize products by engraving or cutting images, letters, or shapes in materials such as wood, metal, glass, and plastic. This allows designers to offer unique, personalized products that stand out on Etsy.

Improved product quality: Laser engravers and cutters help create superior products with clean edges and professional finishes. This can improve your product presentation on Etsy and increase customer confidence in your brand.

Increased Productivity: Laser engravers and cutters produce products more quickly and efficiently, allowing designers to sell more products on Etsy.

New business opportunities: Laser engravers and cutters make it possible to create new products and new designs. Creators can use these machines to explore new business opportunities on Etsy, such as selling personalized, engraved, or die-cut products.

It is important to note that to use a laser engraver or cutter for your business on Etsy for example, it is necessary to have the appropriate experience to use these machines in a safe and effective manner. It is also important to familiarize yourself with the safety standards and regulations in force to guarantee the quality and safety of your products.

In summary, laser engravers and cutters are very versatile production tools that can enhance your business on Etsy by enabling product customization, improving product quality, increasing productivity, and creating new business opportunities. business. It is important to be familiar with these machines and to respect safety standards to guarantee the quality and safety of your products.

Some achievements on different supports

Leather Engraving

Woodcut

Cutting ideas

Creative Paper Engraving

Acrylic Engraving

Metal Engraving

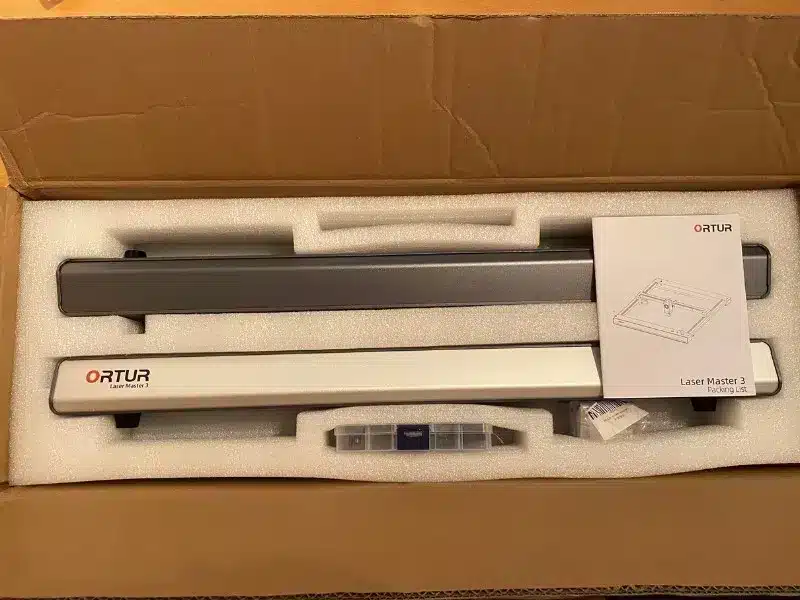

Unpacking and Assembly

The Ortur Laser Master 3 comes in a compact package, weighing 6,5 kg in total, much less than most 3D printers which usually weigh between 13 and 16 kg.

However, it is still heavier than the Ortur Laser Master 2 Pro, which weighed around 4 kg, thanks to its reinforced metal frame the Laser Master 3 has better stability.

The Ortur has a manual in several languages which does not come with the device. Ortur informs us that they have eliminated the paper manual to protect the environment, so you must access it through their website. Only detail parts list comes with.

We're glad to see the Ortur brand put the environment first with paper reduction, but if you don't have an internet connection, this can be problematic.

Assembly time is around 30 minutes, although the first step is a bit tricky to do if you're on your own. You thread a wire through the left side chassis piece, which makes it difficult to get the 4x8mm nut through. But the rest is really easy.

They have made sure to make it even easier to assemble the new laser engraver/cutter compared to the Ortur Laser Master 2 Pro. The frame, belts, and wiring are mostly better organized.

Once I turned the device on, I updated the firmware immediately, which you may need to do as well. You can download the firmware from the Ortur official website, then you just need to turn on the machine and press the reset button to prepare the laser for a firmware update, finally move the files when connected to your PC.

First tests of Ortur's laser engraver / cutter

With all laser engravers, you usually always have a few test pieces to calibrate and test the device before moving on to your projects.

We first tried to engrave a logo on wood. We started with something simple

The settings used were:

- 100mm/s, 20% power

- 100mm/s, 50% power

- 100mm/s, 75% power

The 75% power yielded the best result by far, with a darker, deeper etched background and no burn-in to the intricate letters of the logo.

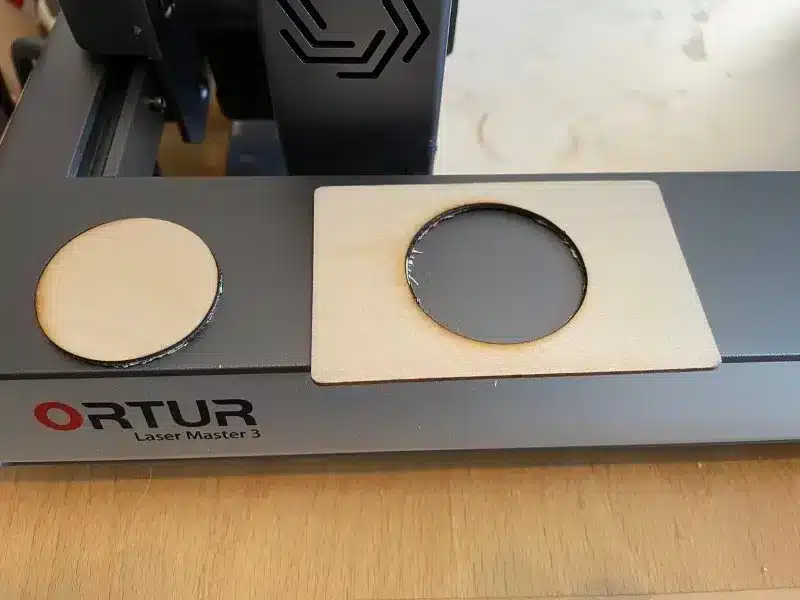

Testing laser cuts with the Ortur Laser Master 3

Circular laser cutting

We were able to see, on 3 mm plywood, the efficiency with which it could cut. We tried, to start, to make a circular shape with the following parameters:

- 60mm/s speed, 80% power and 9 passes. (duration 1.30min)

Laser cutting and engraving on wood

For this test I used a png file found on the web and set the Ortur laser master 3 to engrave at 50mm/s and 80% power for deeper and darker engraving.

For cutting, I used 20mm/s and 87,5% power over 3 passes. (Lightburn Settings)

The engraving took about 10 minutes and to get a clean cut it took 3 passes and it took 4 minutes.

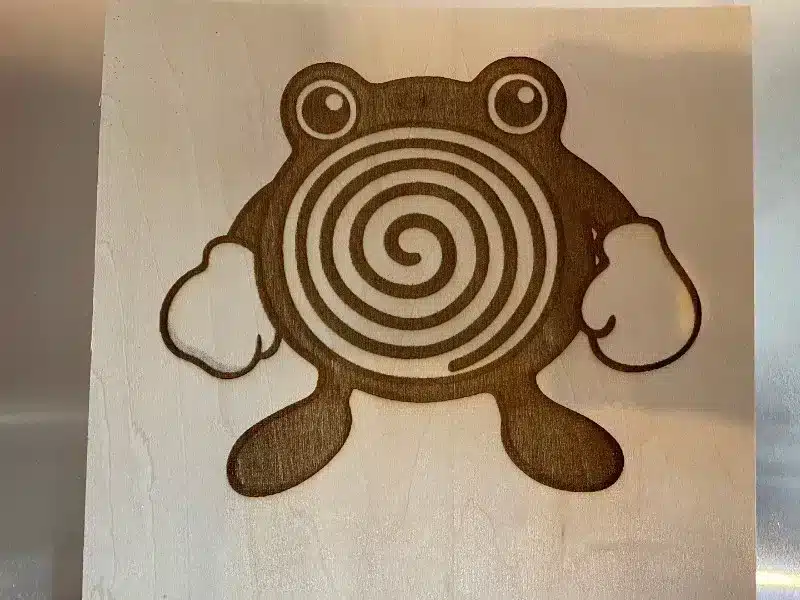

Ortur Laser Master 3 laser engraving tests

With the wood supplied with the Ortur LM3, we tried a larger engraving.

We tried with an image of a Pokémon found on the internet.

The engraving was carried out at 80% power, a speed of 50 mm/s and a single pass. It took about 45 minutes and the result is excellent.

Cutting and Engraving on Acrylic

Acrylic is trickier to cut than wood because it will take several tries to find the right settings. We have engraved on two pieces supplied with the Ortur Laser Master 3. They are approximately 0,1mm and 0,3mm thick black acrylic.

The laser works very well with its support, it has no problem cutting or engraving. The 0.3mm part was cut in 5 passes at 15mm/s and 87,5% power.

Ortur laser master pro2 vs Ortur laser master 3

The Ortur laser master 3 is the best designed laser engraver / cutter to date.

The Ortur Laser Master 2 Pro and the Ortur Laser Master 3 are both high quality laser cutters made by Ortur. Here are some points of comparison between these two models:

- Laser power: The Ortur Laser Master 2 Pro has a laser power of 5.5W while the Ortur Laser Master 3 has a laser power of 10W. This means that the Ortur Laser Master 3 is able to cut thicker materials and engrave faster and more precisely than the Ortur Laser Master 2 Pro.

- Cutting speed: The Ortur Laser Master 3 can cut materials more precisely and faster than the LM2 Pro.

- Cutting precision: Both models have a cutting precision of 0.01mm. But LM3 can cut 30mm acrylic and 20mm wood while LM2 Pro can cut 10mm acrylic and 12mm wood

- Working size: The Ortur Laser Master 2 Pro has a working area of 400 x 400 mm like the Ortur Laser Master 3. This allows you to cut larger parts than the majority of laser cutters in this category

- Software : The Ortur Laser Master 2 Pro is compatible with LightBurn software while the Ortur Laser Master 3 is compatible with several software.

- connectivity:The Laser Master 3 is connectable via WiFi, you can send images to be engraved via the Laser Explorer application, and via an SD card or USB key. The LM2 Pro is only connectable via USB.

- Engraving speed: The Laser Master 3 offers a speed of 20 mm/min, compared to 000 mm/min for the Laser Master 10 Pro.

In summary, the Ortur Laser Master 3 is generally more powerful, faster and with a larger working area than the Ortur Laser Master 2 Pro, but both models have similar cutting precision and are made by the same company. It is therefore important to choose the model that best suits your needs according to your projects and your requirements in terms of power, speed and precision.

The Chassis

The aluminum frame is of good quality and adds stability and therefore precision. Overall, it seems nicer and more professional. We greatly prefer the steel metal look to the previous black acrylic look of the Ortur Laser Master 2 Pro.

Although it does not directly impact the chassis, the location of the emergency stop button on the right side close to the power button is a good thing in terms of ergonomic design and improves safety .

The work area

The Ortur Laser Master 2 and 2 Pro also had working areas of 400 x 400 mm, which is much larger than most devices in this category.

Compared for example to the Two Trees TS3, which is a professional laser cutter of the same range but with a higher price than the LM3. It has a smaller working area of 300 x 200 mm, due to the fact that it is closed and this necessarily affects the size.

Performance: Speed, and Quality of Cutting & Engraving

Cutting and engraving quality

With a focal spot size of 0,05 x 0,1 mm, the OLM3 has an accuracy of 0,01 mm.

While the Ortur Laser Master 2 and Laser master Pro used a less powerful 5,5W laser, the Ortur Laser Master 3 upgrades to 10W.

Just like Snapmaker with their new 10W high power device. This is possible by combining two 5W lasers to produce 10W power.

However, Ortur has revisited both its laser combination technology by combining the lasers into one to achieve 10W and also its laser point compression technology for better accuracy.

This allows for results with a deeper and faster cut. As an example, the Ortur LM3 can cut 30mm thick acrylic and 20mm wooden boards. This allows the cutting of 12mm wood in a single pass, as well as the cutting of 10mm acrylic in a single pass.

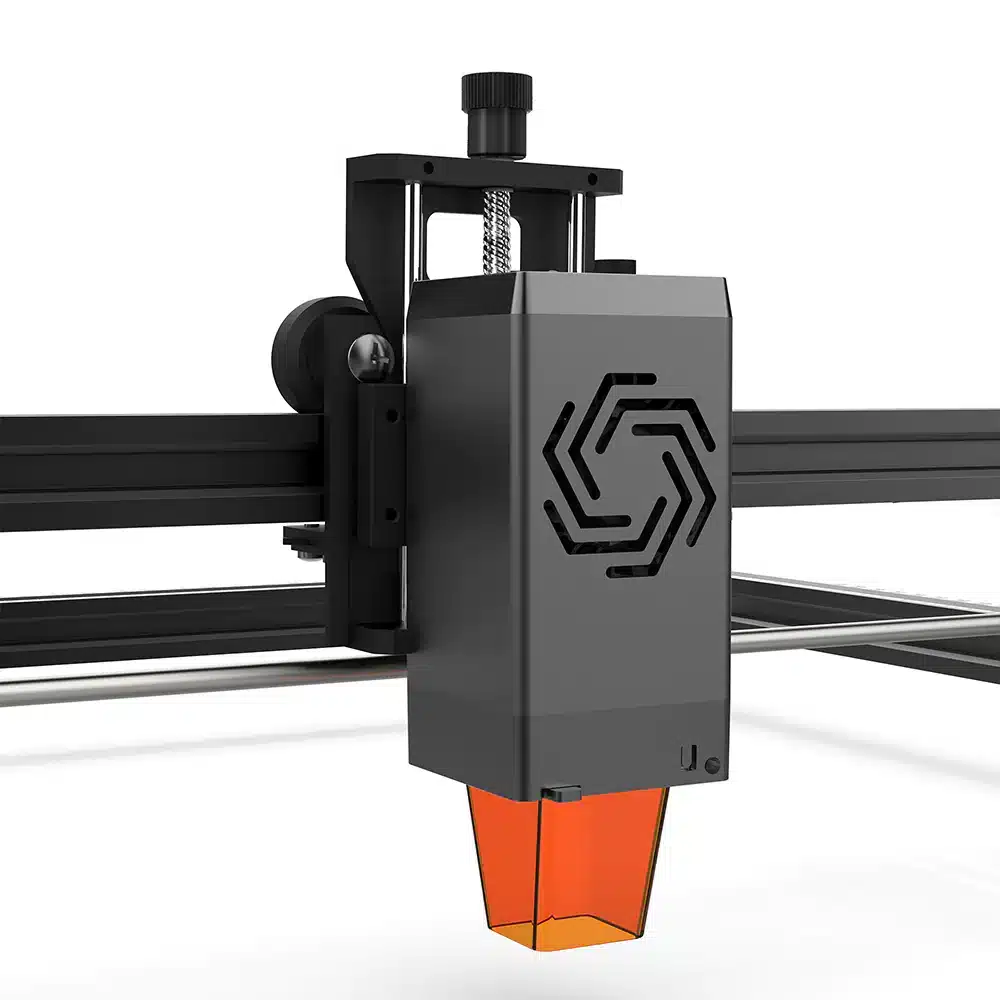

laser-module

The laser module is designed to be very light. It weighs only 235 grams. This keeps it stable, always cool and therefore prevents overheating.

Motherboard

The Ortur Laser Master 3 has the latest ESP-Pro-v2.4 motherboard and is designed to have bi-directional I/O interfaces. The motherboard communicates with other machine components, and through the two-way interface, can inform the motherboard to update the current status, giving you more control and flexibility of the environment.

This is the newly upgraded 11th generation motherboard to handle the increased laser power and maintain it throughout your project. It also prevents overheating or excessive noise, while keeping the project running stable and consistent.

Vitesse

One of the main qualities of the Ortur Laser Master 3 is its maximum speed of 20 mm/min. Other laser engravers claim to be able to achieve these speeds, and technically they can, but without adequate laser power. So you won't be able to print on different materials, at least in downhill quality. With the Laser Master 000 you can still create detailed, high contrast grayscale engravings at this speed.

To give an idea, 20mm/min means burning a 000×100mm image in about 100 minutes. Most competitors running around 10mm/min would take 6000 minutes or more for the same engraving.

The different engraving supports of the Ortur LM3

With the Ortur Laser Master 3 you can engrave:

- Wood

- Acrylic

- Leather

- Metal (stainless steel, aluminum, etc.)

- Ceramics

- Fabric

- Food

- Glass

- Paper and cardboard

- Cylindrical objects like rolling pins and bottles (with the YRR option)

Softwares

The Laser Master 3 is compatible with the following software:

- LaserGRBL – for Windows only. If you are on MacOS, we recommend LightBurn instead, because LaserGRBL is not compatible on MAC.

- LightBurn – this is a paid option, which costs $40. However, we highly recommend LightBurn and used it for this test. It's also the best choice if you're on a Mac and can't use LaserGRBL.

- Laser Explorer – the app is available on Android and iOS smartphones, and connects to your phone so you can send the photos or images you want to engrave.

We used LightBurn, but LaserGRBL is a great option, and if you want to send your projects to the OLM3 via your phone, you can download the Laser Explorer app.

It is easy to connect the Ortur Laser Master 3 via LightBurn. Our Windows laptop automatically detected the laser engraver/cutter and it automatically added the size profile (400 x 400 mm) and front left starting point.

For Mac users, you may need to add the profile manually, but LightBurn is also reliable on Mac.

Connectivity

One of the main advantages of the Ortur Laser Master 3 is its high connection capacity.

Not only can you connect to Lightburn or LaserGRBL via USB, but you can also connect via the Laser Explorer app on your iOS or Android smartphone.

It's really nice that you can directly send all the photos you have taken or all the images from your phone and burn them immediately.

The Laser Explorer app comes with a range of images that you can use freely or you can upload your own and burn them.

The LM3 also has a WiFi connection thanks to the antenna on the side of the machine that you plug in when you assemble it. Any computer or tablet that can launch a browser can connect to your network to control the laser engraver. Simply login to the web server in the firmware of the machine.

The connection options are:

- USB

- SD card

- WebUI

- FTP

- Laser Explorer App

The 7 integrated safety functions:

- Security lock with key

- Active position protection

- Protection in inclined position

- Detection and limitation of exposure time

- Current Voltage Safety Control

- Connection Host Control

- Emergency stop switch

The emergency stop switch is a great safety addition that comes with the Ortur Model Laser Master 3. Some see it as a premium addition because not all devices do. If we take the Snapmaker 3 – 2.0-in-3 1D printer as an example, the emergency stop button is optional and if you want it, you have to pay extra for it. If you ever have a problem with your LM3, just press the button and your project will stop immediately.

The security lock allows you to lock or unlock the OLM3 with the key. And there are other safety features that show that the OLM3 is a safety-oriented laser engraver.

The accessories of the Ortur laser engraver / cutter

Laser engraving platform

Advantages:

- Protect the desktop from damage

- Fast heat dissipation, exhaust smoke left and right

- Get clean engraving, cutting and results

The engraving platform under your Ortur laser engraver / cutter allows you to avoid damaging surfaces.

Open laser engravers like the LM3 which is caseless need a surface underneath to prevent you from burning your table or desk. Some use saver board or other homemade DIY solutions.

Using a specially designed platform has made the laser engraving and cutting process so much easier. It also allows for perfect engraving and cutting. Homemade options can be slightly uneven surfaces, which may have a (minimal) effect on overall performance.

Rotating roller

Benefits

- Multi-mode Y-axis rotary chuck.

- The elevation angle can be adjusted 180°, the rotation is 360° without disassembly.

- Can be used for rings, mugs with handles or irregular items, etc.

- Engraving accuracy 0,45°, engraving diameter range up to 120mm.

- Aluminum alloy material, one-piece structure.

- Easy to install, robust and reliable.

We highly recommend this accessory for your Ortur Laser Master 3 laser engraver/cutter if you plan to engrave something round like glasses, bottles or tumblers, gift boxes or anything else. These personalized items are selling very well.

We only used the rotary roller very briefly. What we did with it was only a test of a small etch to try out the contrast We are planning to try the roller on the glass will update this article with a demo video.

If you want to engrave something cylindrical like glasses or beakers, this is the best option. These original pieces are snapping up on Etsy! Here are some original ideas

Air pump

Advantages:

- 50 l/min air outlet.

- Used to clean cutting residue to achieve clean, clean edges.

- Clear the smoke

- Better protects the laser lens and improves the cutting power.

We have also used the air pump with the Ortur Laser Master 3. It is a high quality pump which for deeper cuts is a godsend. Typically, in short, an air pump helps dissipate the heat from the laser so it isn't as focused on your wood or other materials you're cutting.

This prevents charred black marks on the corners and sides of your cuts. It can also help you make deeper cuts faster.

Housing

Advantage:

- Fibrous and flame retardant.

- Easy to fold and very quick assembly.

- Can be used with the Laser Explorer app. Allows you to directly control the light switch and fan button.

The box is ideal from a security point of view thanks to its robust structure. It also has exhaust fans that maintain high airflow and reduce noise, and an exhaust pipe to extract fumes. It's also easy to transport, making it more portable and ideal for storing your device if you're moving from workshop to workshop.

Height adjuster

Benefit

- Device for adjusting the height of the laser module.

- Very convenient to adjust the focal length of the laser module.

With this accessory that you install on the top of the laser head, it greatly facilitates the adjustment of the height of the laser head. This makes calibrating the focal length much more accurate and easier. It also increases your travel range by 57mm with the laser, allowing you to engrave thicker materials.

Did you enjoy this comparison? Share it 😉

This guide has taken you through the best laser engraver/cutter. We hope you enjoyed it. If you found it interesting and useful, then feel free to share it with your friends and loved ones. Stay connected to neuf.tv for always more information, tests and trials.

You might also be interested in: The best cheap gaming laptop